|

夹压辊压力测量

Capture and measure nip pressure distribution with pressure mapping.

压力分布的捕捉和测量压力分布。

Nip Pinch Machine Setup, Roller Alignment, and Pressure Distribution

夹点机的设置,辊对准,和压力分布

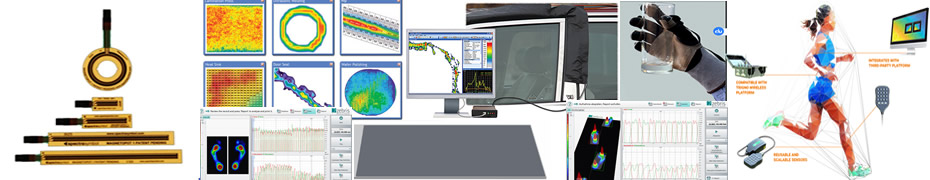

Tekscan tactile pressure sensors are excellent tools for measuring nip profiles, force or pressure variations along a roll axis. The software measures and displays in real-time the static forces in a pinch roll nip. For many large machines, nip contact is adjusted by setting hydraulic pressure at contact units located on the ends of the rollers. In the absence of measurements, the relationship between hydraulic pressure and nip force is assumed to be linear. Drag in the linkage and other sources of hysteresis are not quantified.

Tekscan压力传感器测量触觉夹型材优良的工具,沿辊轴力或压力的变化。实时的软件措施,并显示在实时的静态力量在捏辊夹。对于许多大型机器,通过设置在辊端部的接触单元设置液压压力来调整接触压力。在测量的情况下,液压压力和夹持力之间的关系被假定为是线性的。拖在联动和其他来源的滞后是没有量化。

Tekscan sensors measure nip force and width at locations along the axis at various hydraulic pressures providing real-time feedback on a PC. The detection of crowning and differences in pressures and contact width along the length of the roll can be documented. These measurements improve costs by reducing machine set-up time, down time and product scrap.

Tekscan传感器测量的夹持力和宽度的位置沿轴线各液压压力对PC在沿辊身长度的压力和接触宽度的加冕和差异的检测可以提供实时的反馈记录。这些测量提高成本,减少机器设置时间,停机时间和产品废料。

Tekscan’s patented, thin-film, pressure sensors are available in different shapes and pressure ranges, are reusable, and provide accurate pressure data.

Tekscan的专利,薄膜压力传感器有不同的形状和压力范围内,可重复使用,并提供准确的压力数据。

Tekscan offers two solutions for nip and roller pressure measurement: I-Scan® and NPMS™.

Tekscan提供夹辊压力测量解决方案:扫描®和网™。

I-Scan Pressure Mapping System

I-Scan压力映射系统

I-Scan is a versatile solution for optimizing a process or manufacturing parameters. With a wide range of sensor form factors and data analysis tools in the software, I-Scan is a powerful tool for a research and development team to improve yield.

扫描是一个通用的解决方案来优化工艺或制造参数。与范围广泛的传感器的形式因素和数据分析工具软件,扫描是一个研发团队提高产量的有力工具。

Ideal for engineering team analysis

工程团队分析的理想

Over 200 sensors to choose from in different shapes and pressure ranges

超过200个传感器,选择从不同的形状和压力范围

Real-time display of pressure sensor data

压力传感器数据的实时显示

Recording & playback of dynamic pressure images

动态压力图像的记录与回放

Fast (100 Hz) sensor scanning

快速(100赫兹)传感器扫描

I-Scan System in Use

在使用扫描系统

I-Scan system in use

在使用扫描系统

I-Scan Software Output

扫描软件输出

I-Scan Software Output

扫描软件输出

Nip Pressure Measurement System (NPMS)

夹持压力测量系统(下)

NPMS is a packaged solution which provides real-time roller profile status for nip pressure measurement. The convenient housing of the system allows a manufacturing operator to easily make adjustments prior to a production run. A calibrated profile can be saved to the PC as a reference, removing the guesswork out of setup.

网是一个打包的解决方案为钳口压力实时测量辊形状态。该系统的方便的住房,允许生产经营者在生产运行之前,容易作出调整。校准曲线可以保存到PC机作为参考,去猜测出的设置。

Ideal for measurements performed by production team

由生产团队进行测量的理想

Portable wireless solution that can be moved from place to place around the plant

便携式无线解决方案,可以从地方移动到周围的工厂

Frame capture of pressure distribution

压力分布的帧捕获

Easy to manage housing with wireless communication

易于管理的住房与无线通信

NPMS System in Use

在使用网系统

NPMS System in use

在使用网系统

NPMS Software Output

网络性能管理系统软件输出

NPMS Software Output

网络性能管理系统软件输出

Nip Pinch Pressure Measurement Applications

夹压测量应用

Nip pressure profile

压型

Identify roller contact pressure

确定辊接触压力

Determine roller contact area

确定辊接触面积

Determine nip width

确定咬宽度

Before and after adjustment comparison

调整前后比较

Machine to machine comparison

机器比较

Validation testing

验证测试

|